When it comes to industrial water storage, protecting the water from contamination, evaporation, and environmental damage is crucial. I’ve seen how industries struggle with water quality issues simply because their storage systems lack proper protection. That's where an air proof FRP water tank cover comes into play. It's more than just a lid—it's a solution that enhances the efficiency and safety of industrial water storage.

In this blog, I’ll walk you through why these covers are essential, how they work, and why they’re becoming a go-to choice for industries. Along the way, I'll also talk about how FRP barrel type huts and FRP gas collector gutters fit into the picture.

Why Air Proof FRP Water Tank Covers Matter

I’ve seen many industries use traditional tank covers, only to face problems like water contamination, algae growth, and evaporation. An air proof FRP water tank cover solves these issues effectively. Here’s how:

Prevents Contamination: The airtight seal keeps dust, debris, and insects out of the tank.

Reduces Evaporation: By blocking airflow, water loss due to evaporation decreases significantly.

Maintains Water Quality: No exposure to external pollutants means cleaner, safer water.

Durable and Long-Lasting: FRP (Fiber Reinforced Plastic) is resistant to corrosion, weather, and UV damage.

For industries relying on large-scale water storage, these benefits translate to lower maintenance costs and better operational efficiency.

How Do Air Proof FRP Water Tank Covers Work?

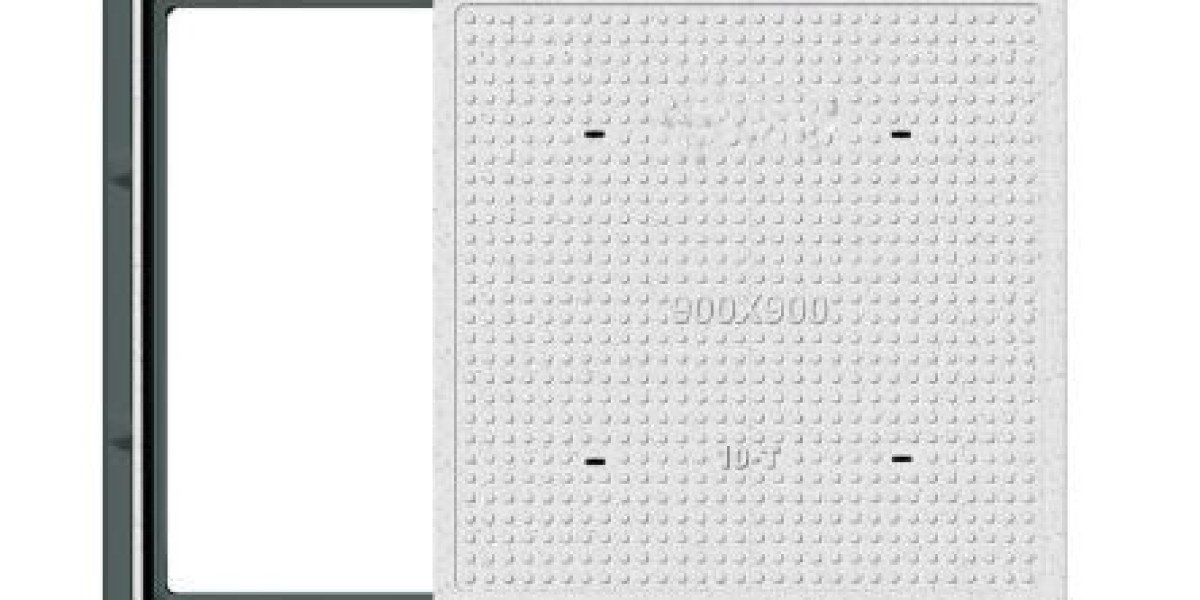

The design of an air proof FRP water tank cover is simple yet highly effective. It’s crafted from high-strength FRP material, ensuring durability while maintaining a lightweight structure. The cover fits snugly over the tank, creating an airtight seal that prevents air and external contaminants from entering.

Here’s a breakdown of how it works:

Sealed Edges: The edges are designed to fit perfectly around the tank, leaving no gaps.

Ventilation Control: While airtight, the cover can include controlled ventilation to prevent pressure build-up.

Weather Resistance: FRP material resists extreme temperatures, rain, and UV rays.

With such a design, industries can store water without worrying about quality degradation.

Complementing Solutions: FRP Barrel Type Huts and Gas Collector Gutters

While the air proof FRP water tank cover protects the top of the tank, other FRP solutions support overall industrial water management. Two key components I’ve found useful are:

1. FRP Barrel Type Hut

These structures offer shelter for water treatment units, pumps, and other industrial equipment. They’re:

Lightweight yet sturdy

Corrosion-resistant

Easy to install and maintain

I’ve seen industries use FRP barrel type huts to house filtration units alongside their water storage tanks, ensuring the entire system remains protected.

2. FRP Gas Collector Gutter

In industries dealing with wastewater or chemical storage, gas accumulation can be a problem. FRP gas collector gutters play a crucial role by:

Collecting and venting harmful gases safely

Preventing gas build-up around storage tanks

Enhancing workplace safety

Pairing these with an air proof FRP water tank cover creates a comprehensive storage solution.

Benefits for Industrial Applications

From my experience, industries like manufacturing, food processing, and pharmaceuticals benefit the most from air proof FRP water tank covers. Here’s why:

Cost Savings: Less water loss means lower refilling costs.

Reduced Maintenance: No algae growth or contamination to clean.

Enhanced Safety: Airtight covers prevent accidental spills and exposure.

Long-Term Durability: FRP materials withstand harsh industrial conditions.

How to Choose the Right FRP Water Tank Cover

If you’re considering an air proof FRP water tank cover for your industrial setup, here’s what I’d recommend looking for:

Proper Fit: Ensure the cover is custom-made for your tank dimensions.

High-Quality FRP: Look for covers made from premium, UV-resistant FRP.

Airtight Seal: Check if the cover provides a complete seal without gaps.

Easy Installation: Choose covers designed for quick and hassle-free installation.

I’ve found that investing in the right cover upfront saves significant costs down the line.

Installation and Maintenance Tips

Installing an air proof FRP water tank cover is straightforward, but a few tips can ensure it performs at its best:

Ensure a Clean Surface: Before installation, clean the tank's rim to ensure a tight seal.

Check for Damage: Inspect the cover regularly for cracks or wear.

Maintain Ventilation: If the cover has ventilation ports, keep them clear of debris.

With minimal maintenance, these covers can last for years without losing efficiency.

Final Thoughts

Switching to an air proof FRP water tank cover has been a game-changer for many industries I’ve worked with. It’s not just about covering a tank—it’s about ensuring water quality, reducing costs, and improving overall operational efficiency.

Paired with FRP barrel type huts for equipment protection and FRP gas collector gutters for safe ventilation, these covers create a comprehensive water storage solution.

If you’re managing industrial water storage and still using traditional covers, now’s the time to upgrade. Trust me—your tanks, your water, and your bottom line will thank you.