As the world increasingly turns to renewable energy sources, solar power manufacturing stands at the forefront of this transformation. Innovations in technology and processes are not only enhancing efficiency but also promoting sustainability within the industry. This article delves into the key advancements shaping the future of solar power manufacturing.

Advancements in Solar Panel Technology

One of the most significant areas of innovation in solar power manufacturing is the development of advanced solar panel technologies. Traditional silicon-based solar panels have dominated the market for years. However, new materials such as perovskite are emerging, offering higher efficiency rates and lower production costs. These advancements raise an important question: how will these new technologies impact the overall solar market?

- Higher Efficiency: Perovskite solar cells can achieve efficiencies exceeding 25%, compared to the 20% typical of conventional panels.

- Lower Costs: The manufacturing process for perovskite cells is less resource-intensive, potentially lowering costs for consumers.

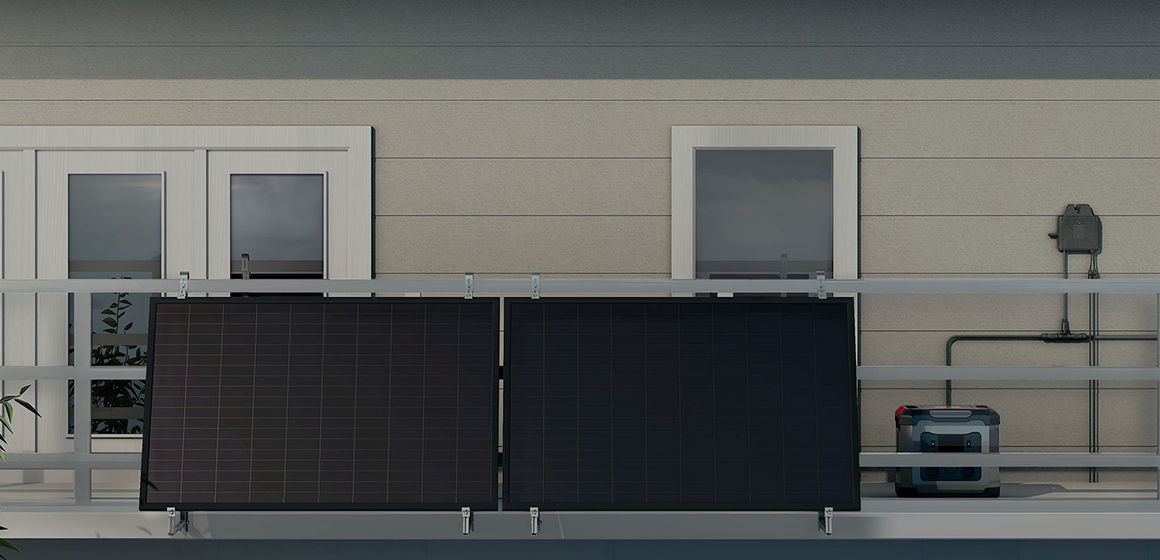

- Flexible Applications: New materials allow for flexible solar panels that can be integrated into various surfaces, from rooftops to vehicles.

Automation and Smart Manufacturing

Another critical aspect of solar power manufacturing is the integration of automation and smart manufacturing techniques. By utilizing robotics and artificial intelligence, manufacturers can streamline production processes, reduce waste, and enhance quality control. This leads to a more efficient manufacturing cycle. What are the implications of these technologies for the workforce in the solar industry?

While automation may reduce the number of manual labor jobs, it also creates opportunities for skilled positions in technology and maintenance. Companies that embrace these innovations are likely to see improved productivity and profitability.

Sustainability in Solar Power Manufacturing

As the demand for solar energy grows, so does the need for sustainable practices in solar power manufacturing. Manufacturers are increasingly focusing on reducing their carbon footprint and utilizing eco-friendly materials. This shift is not only beneficial for the environment but also aligns with consumer preferences for sustainable products.

- Recycling Programs: Many manufacturers are implementing recycling programs for old solar panels, reducing waste and promoting circular economy principles.

- Eco-Friendly Materials: The use of non-toxic and sustainable materials in production processes is becoming more common.

- Energy Efficiency: Manufacturers are optimizing their energy use, often incorporating renewable energy sources into their operations.

The Role of Policy and Investment

Government policies and investments play a crucial role in shaping the future of solar power manufacturing. Incentives for research and development, as well as subsidies for solar installations, can drive innovation and adoption. How can policymakers ensure that the solar industry continues to thrive?

By fostering an environment that encourages investment in renewable technologies, governments can help accelerate the transition to a sustainable energy future. Collaboration between public and private sectors is essential for maximizing the potential of solar power.

In conclusion, the future of solar power manufacturing is bright, driven by innovations that enhance efficiency and sustainability. As the industry evolves, staying informed about these advancements is crucial for stakeholders at all levels. For more insights into solar technologies, visit  .

.