In recent years, the advent of large 3D printers with high resolution has revolutionized the manufacturing landscape. These advanced machines are not only capable of producing intricate designs but also offer unparalleled precision and efficiency. As industries continue to evolve, understanding the implications of these technologies becomes essential.

What is a Large 3D Printer with High Resolution?

A large 3D printer with high resolution is designed to create sizable objects with exceptional detail. Unlike traditional 3D printers, which may be limited in size and resolution, these machines can produce large-scale components while maintaining a high level of accuracy. This capability opens up new avenues for various sectors, including aerospace, automotive, and healthcare.

Key Features of Large 3D Printers

- High Resolution: These printers can achieve layer resolutions as fine as 20 microns, allowing for intricate designs.

- Large Build Volume: Capable of printing objects that are several feet in size, they cater to industries requiring large parts.

- Material Versatility: They can work with a wide range of materials, including plastics, metals, and composites.

- Speed and Efficiency: Advanced printing technologies enable faster production times without compromising quality.

Applications of Large 3D Printers with High Resolution

The applications of large 3D printers with high resolution are vast and varied. In the aerospace industry, for instance, these printers can produce lightweight components that enhance fuel efficiency. Similarly, in healthcare, they are used to create custom prosthetics and implants tailored to individual patients.

Benefits of Adopting Large 3D Printing Technology

Integrating large 3D printers with high resolution into manufacturing processes offers several benefits:

- Cost Reduction: By minimizing material waste and reducing the need for multiple manufacturing steps, companies can significantly lower production costs.

- Customization: These printers allow for the production of bespoke items, catering to specific customer needs.

- Shorter Lead Times: Rapid prototyping capabilities enable quicker turnaround times from design to production.

Choosing the Right Large 3D Printer

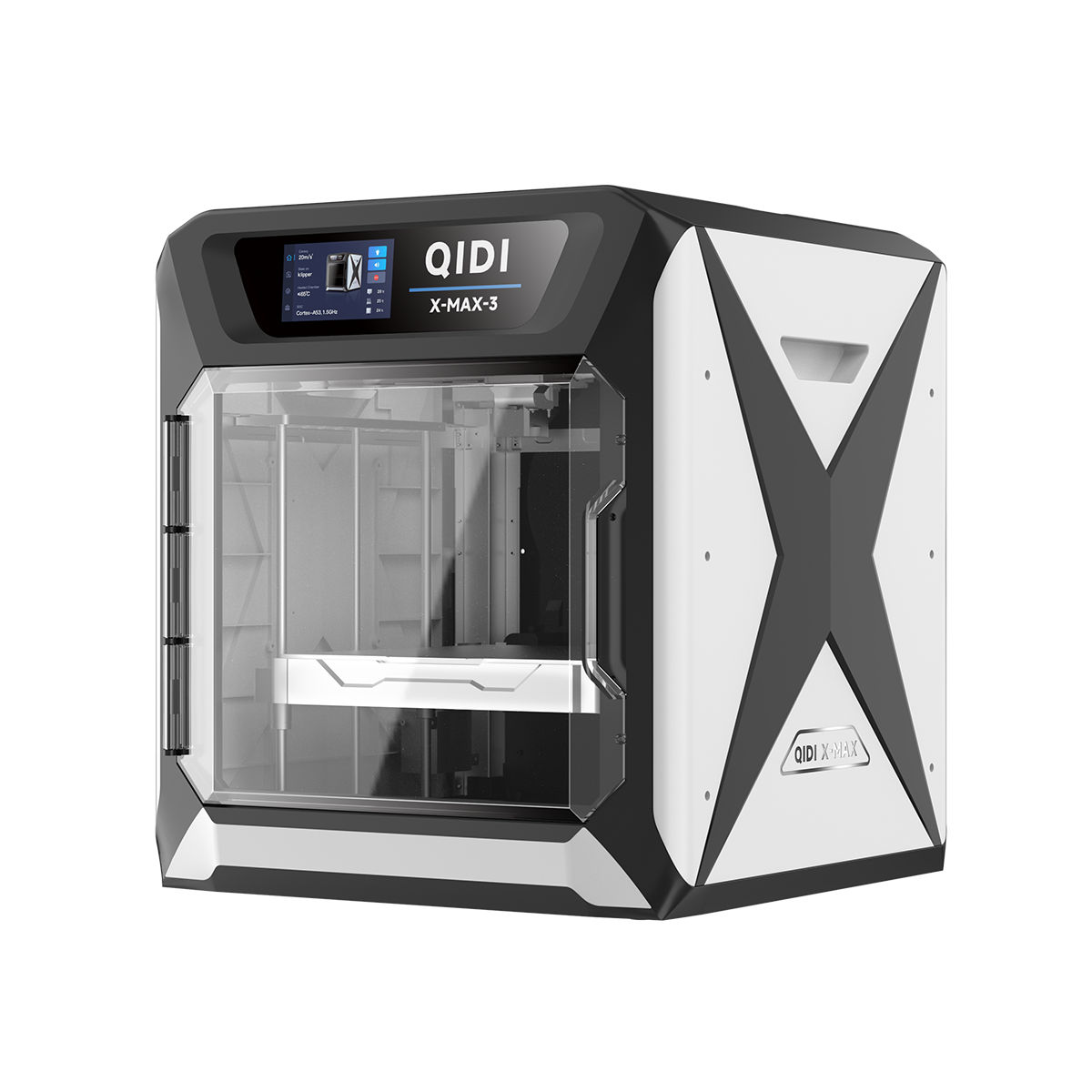

When selecting a large 3D printer with high resolution, it is crucial to consider factors such as build volume, material compatibility, and resolution capabilities. One excellent option is the  , which combines these features to deliver outstanding performance.

, which combines these features to deliver outstanding performance.

The Future of Manufacturing

As we look to the future, the role of large 3D printers with high resolution in manufacturing will only grow. With continuous advancements in technology, we can expect even greater precision, speed, and efficiency. Industries that embrace these innovations will likely gain a competitive edge, paving the way for a new era of production.

In conclusion, understanding the impact of large 3D printers with high resolution is essential for anyone involved in manufacturing. By leveraging these technologies, businesses can enhance their operations and meet the evolving demands of the market.