Plastic Molded Concepts is one of the very few plastic injection molders in the U.S. (and the world) who uniquely specializes in engineering grade resins. PMC provides plastic injection molding services for mission-critical parts that play vital roles in markets like aerospace, military/defense, medical, automotive, electronics and more. Check out our case studies to learn how we have helped customers overcome complex plastic molding challenges. If gate size is not sufficient, it can cause defects like mold warpage and/or black streaks in the molded part. When plastic is injected directly into the cavity with a heat-controlled nozzle, the molded part is far less likely to have dimensional or surface blemishes, like black streaks.U.S. Plastic Molding Company Specializing in Engineered Resins Plastic Molded Concepts is a U.S based company that uniquely specializes in molding with engineered resins. We have been thriving in the plastic molding business for 45 years. We have the experience and certified in-house Master Molders, allowing us to take on projects of any complexity. Solution: To prevent mold warpage, increase the mold temperature based on the resin supplier’s recommendations and then adjust accordingly. Operators should allow 10 cycles for every 10 degree change in order to allow the process to re-stabilize.

What Causes Bubbles In Plastic Injection Molding

Pretty soon I was promoted up to a Material Handler. After that I was trained to be a person that sets the molds in the machines. Within a year I was starting the machines and training new operators! Sometimes, additional gates must be added in order to reduce pressure loss & reduce molded-in stress.Problem: Lack of Ejection Uniformity Engineering failure analysis through forensic insights is invaluable for uncovering hidden issues within plastic injection molded products. By conducting forensic research, laboratory analysis can uncover resin issues leading to product failure. In addition to material assessments, mold inspections, process monitoring, defect analysis, and historical data reviews help manufacturers identify the causes of product failures and prevent them from recurring. In the dynamic field of plastic injection molding, engineering failure analysis through forensic research plays a critical role in ensuring the success of projects across diverse industries. If the operator opens the gate too soon and the product is ejected before the material incurred proper and even cooling time, the operator has shortened the process cycle. An inconsistent process cycle can lead to uncontrolled shrinkage rates, which then causes mold warping. In plastic injection molding, ABS resin is often included in polymer blends to achieve optimal property benefits.Markets Driving the Demand for ABS Plastic Injection Molding

How To Cost Injection Molding

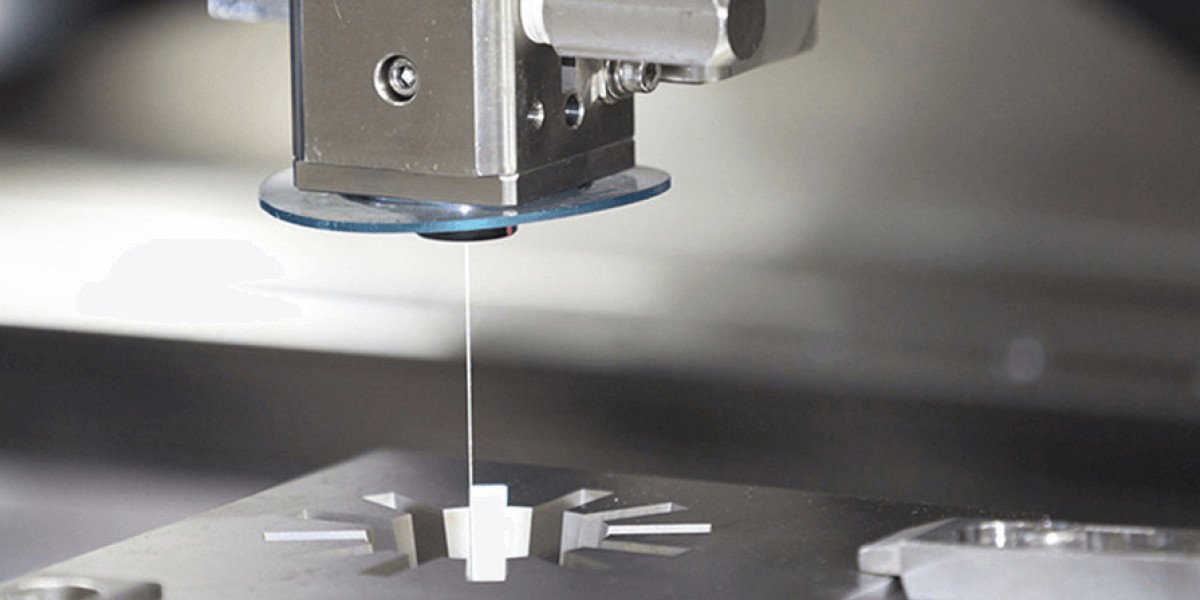

To prevent design and quality challenges before the molding process even begins, it is imperative to partner with an experienced plastic molding company early in the plastic injection mold design process. A seasoned plastic molder will be able to provide manufacturability feedback and provide solutions for the correction of improper mold design. By getting them involved early, you can expect fewer changes after the molding process commences which helps to lower material and labor costs. Furthermore, it will help you avoid dreadful end-use product failures and expedite time to market. Below are some important aspects to keep in mind.Injection Mold Design GuidePart Use & Purpose Plastic injection molders – whether lacking the experience, adept knowledge or proper equipment – can produce defective products that don’t stand up to industry regulations, appearance requirements, and/or general client expectations. In the PMC facility, Sawyer picks a part from the press and puts it on a computer numerical control (CNC) machine for holes to be drilled, detects when it is finished and places the part in a box. Sawyer waits until there are exactly 160 parts in the box, then pauses for an operator to come pick it up. The operator gives Sawyer a push to signal that it can continue, and the process repeats. Some plastic engineered resins being used to replace metals include:ABSAcetal Copolymer (POM)Acrylic (PMMA)LDPEPAIPEEKPETPURPPS Whether it’s improper gate size or positioning, injection molding gate defects can become extremely expensive and time-consuming.